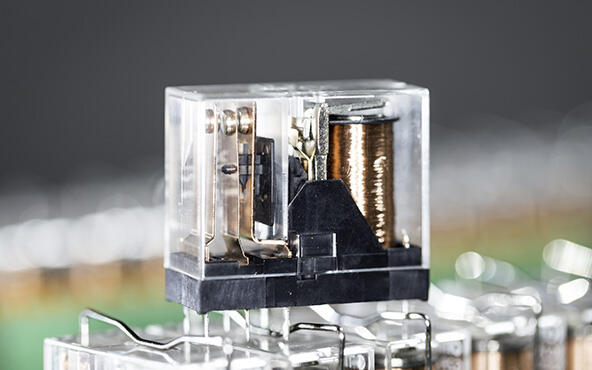

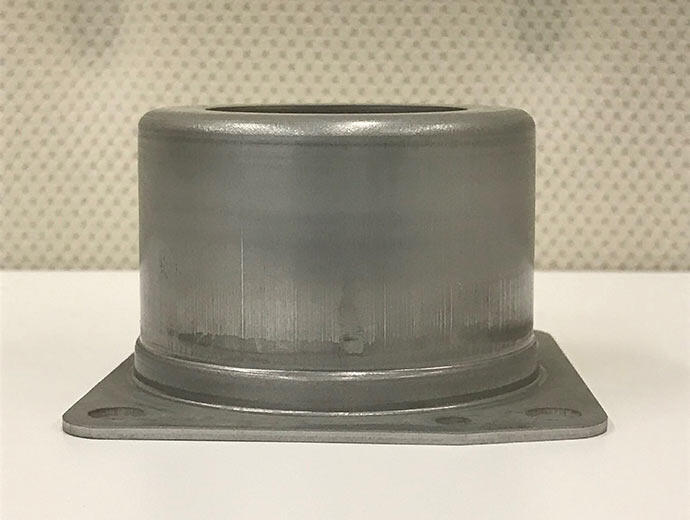

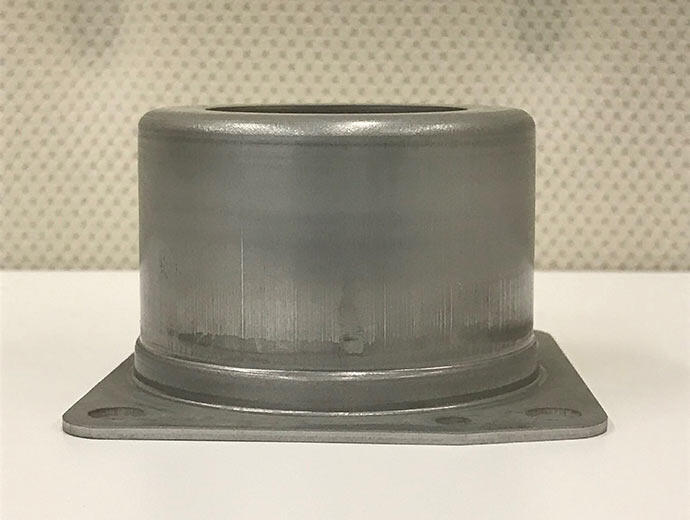

Deep drawing, press components (component combination, machineless forging)

The precision deep drawing technology is one of the metallic plate forming methods, which applies pressure to a thin metallic plate and squeezes it to make it concave to produce a vessel with a bottom. One of its features is the forming of seamless products.

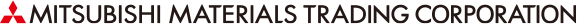

The products are used for automotive parts.

Mobility Parts

Features

- Not only general materials made of metal, copper, and aluminum but also materials made of stainless steel, pure titanium, Inconel, etc. are supported, which fulfill the following needs:

- Products previously made by welding two parts together can be manufactured as one piece using a press.

- Products that were conventionally manufactured by machining can be VA with a press.

Applications

- Automotive parts

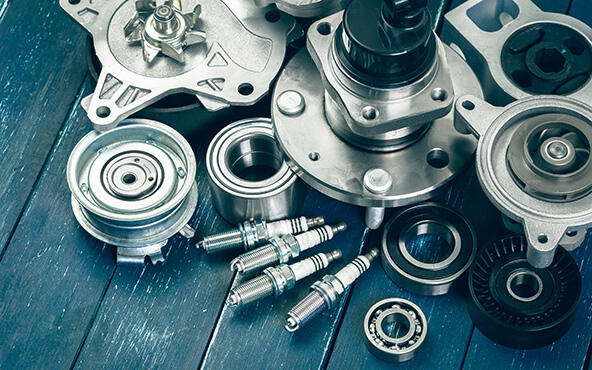

- Motor casings

- Motors for household appliances

- Seat sensors of gas ranges

- Boil-over sensor

- Gas water heaters, etc.

Product Specifications/Summary

The sizes we are capable of handling vary depending on the material. We have press machines with press capacities ranging from 10 t to 400 t.

In addition, it is also possible for us to deep draw up to 100 μm.

We support everything from prototyping to mass production and can provide services beginning from mold designing.

Inquiries regarding this product

Case Studies

FAQ