Sintered parts for automotive components

Home

Product

Metal Materials Manufactured Goods

Metalworking products

Sintered parts for automotive components

Sintered parts for automotive components

Sintered parts for automotive components

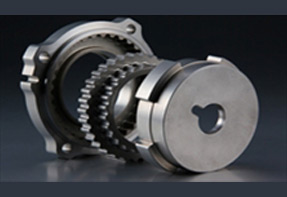

VVT (variable valve components)

VVT assembly

Sintered parts for automotive components

Sintered parts for automotive components

Features

These sintered parts for automotive components are well suited for cost-efficiency gains through mass production.

- It is possible to manufacture near net shaped raw materials by using high-precision dies. Total costs can be lowered by reducing cutting processes.

- Assembly costs can be reduced by combining two or more parts.

- Cost reductions are possible through mass production.

- An endless number of materials can be created by mixed materials.

- Precision parts with complex 3D shapes can be produced even though the manufacturing method is more suited to mass production than machining.

- Sintering can create composite materials not possible with melted alloys and help further optimize materials.

- Sintering is environmentally friendly because the manufacturing process prevents material from being wasted.

Applications

- Components for automibile

- Stainless steel sintered parts

- Sintered parts for VVT: uses iron parts with high mechanical strength

- Sintered parts for EGR: uses special stainless-steel alloy parts

- Sintered parts for VGT: uses iron parts with high mechanical strength

- Sintered parts widely used in other industrial machinery and transport machinery

More specific application examples

- Oil pump rotors

- Variable valve components

- Sprockets

- Pulleys

- Housings

- Various oil pump rotors

- Plate interlocks

- Clutch hubs

- Steering

- Transmission components (AT / MT)