Smelting-related parts and materials

We handle a range of products including protectors for metal electrolysis, lead anodes, and molten metal immersion type optical fiber thermometers.

[Product line]

- Snapjaws™ protector for metal electrolysis (edge masking)

- Lead anode

- Optical fiber thermometer

- A wide variety of electrolytic components

Industrial Equipment, Smelting Technology Products, and Auxiliary MaterialsIndustrial Equipment, Smelting Technology Products, and Auxiliary MaterialsOur Focus Products

Features

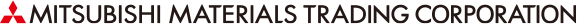

■Snapjaws™ protector for metal electrolysis (edge masking)

The protector for metal electrolysis (edge masking) was developed, improved and begun to be used practically by Mitsubishi Materials Corporation to enable the smelters of its Group to increase their productivity.

Users of the product include overseas customers as well as almost all of the copper smelters and electrolysis plants for other metals in Japan. Based on this track record, we will propose solutions in line with your use environment

The Snapjaws™ protector for metal electrolysis (edge masking) achieves a long service life with the materials that excel in terms of heat, chemical and impact resistance and a molding technology that is excellent in terms of dimension precision. It minimizes maintenance costs for operations, contributing to the reduction of total cost.

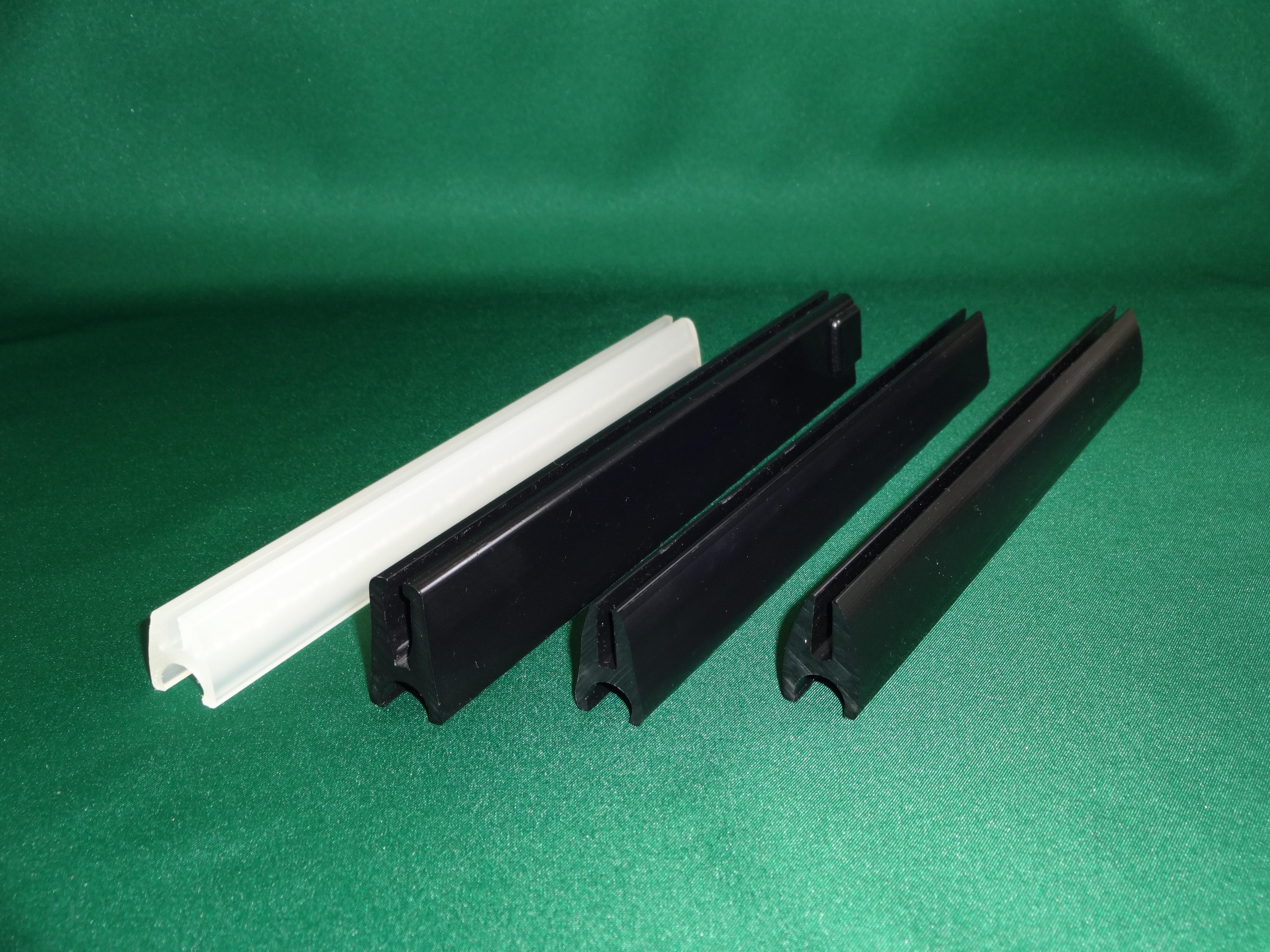

■Lead anode

Based on the track record established by the Mitsubishi Materials Group, we propose and provide specifications in line with your needs.Many copper smelters in Japan use our products which are offered with specifications tailored to the customer's needs.

In addition to the conversion into sheets by rolling or continuous casting with the optimum alloy composition, we are ready to provide products tailored to the customer's needs, including welded sheets and crossbars, to contribute to longer service life and other benefits.

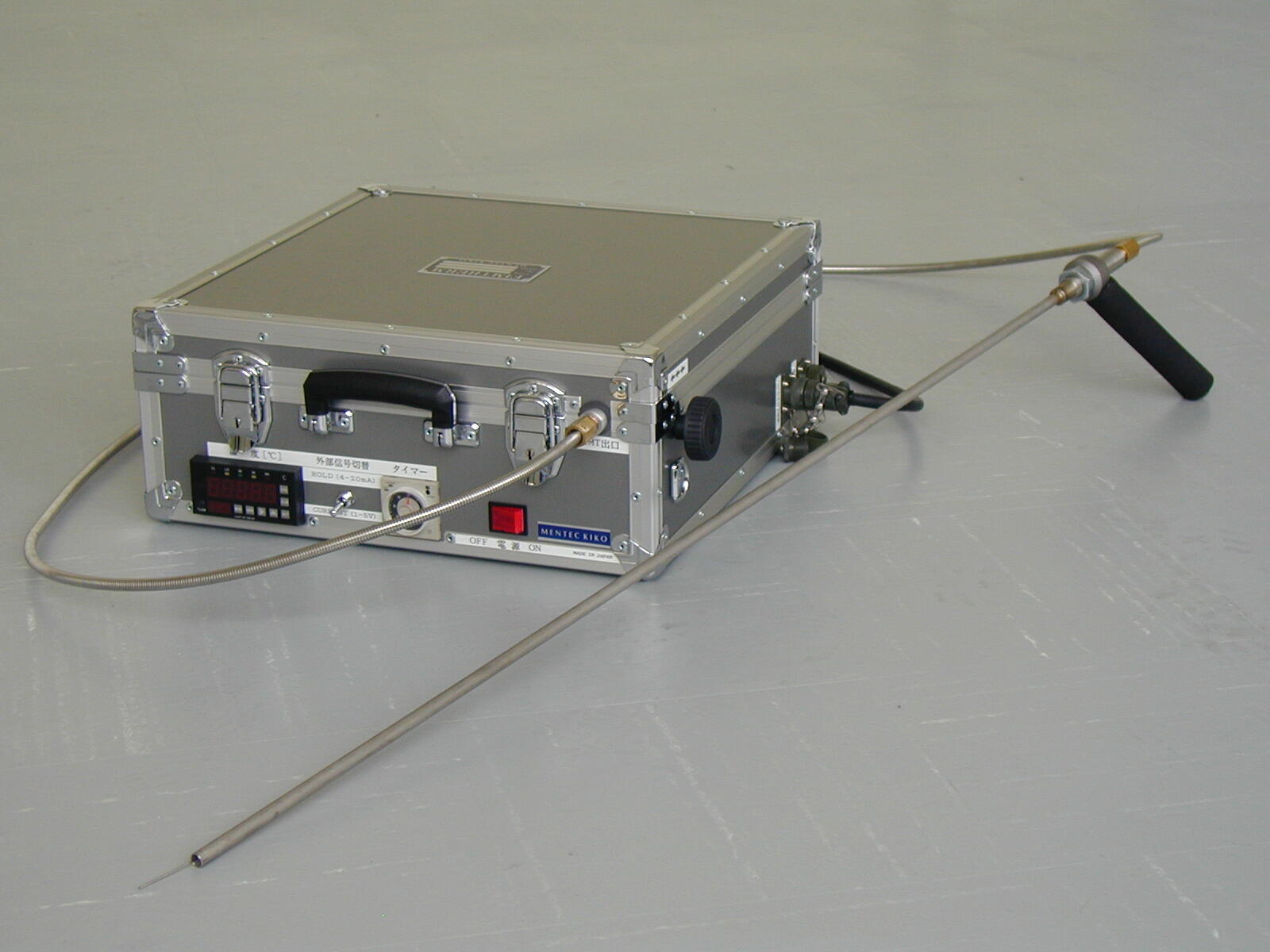

■Optical fiber thermometer

A sensor is directly immersed in molten metal to quickly measure temperature.It is a radiation thermometer using a fiber in metallic tube (FIMT) sensor.The response time is as quick as approximately 0.02 seconds. To measure temperature, the FIMT is directly immersed in molten metal. This ensures a quick and accurate temperature measurement not influenced by disturbances or emissivity.

- It ensures a high-speed response as fast as about 0.02 seconds.

- The high-speed response realizes quick temperature measurement, permitting highly frequent or stream temperature measurement and reducing the burden on measurers.

- The sensor can be regarded as a black body cavity because it is directly immersed in the molten metal, eliminating the need for emissivity adjustments.

In addition to the conversion into sheets by rolling or continuous casting with the optimum alloy composition, we are ready to provide products tailored to the customer's needs, including welded sheets and crossbars, to contribute to longer service life and other benefits.

■A wide variety of electrolytic components

We provide peripheral components for electrolytic cells, such as insulating plates and crossbars.We provide peripheral components for electrolytic cells in consideration of the environment of use, such as insulating plates and other resin products and crossbars and other processed copper products. We also consider offering other products outside our current lineup in line with your needs.

Applications

It is a masking material that prevents metal electrodeposition on both ends and the bottom of cathode plates to facilitate electrodeposited metal stripping in metal electrolysis.

Lead anode

It is used as insoluble anode to transmit electrical current in metal electrolysis for electrowinning.

Optical fiber thermometer

It measures the temperature of molten metal in various places such as within furnaces and hot liquid outlets.The product has also been used in the casting industry and research institutions, for purposes such as the measurement of temperatures in weld pools during welding.

Main Products and Their Applications

| Products | Applications |

|---|---|

| Crossbars | Copper bars for hanging electrode plates |

| Anode spacers | Spacer for preventing contact between copper anodes and cathode base plates |

| Cathode base plates for negative plates | Cathode base plates used for negative plate electrolysis |

| Insulators (insulating plates) | Resin plates for isolating distributors and crossbars |

| Distributors (conductors) | Conductors for transmitting current |

| Flame-retardant resin underlay insulators | Flame-retardant resin plates for isolating electrolytic cells and distributors |