MITSUBISHI MATERIALS HARDMETAL's 「Button Bit」

For the better productivity from optimum design of bit.

- Challenges faced by customer

-

With technological advancement in drilling industry, customers face challenges of productivity in operations. In drilling project, the selection of tools is critical to realizing a higher productivity.

Solution

Mitsubishi Materials Trading Corporation understands and supports the customers needs.

Proposal of optimum bit design

With cooperation of MITSUBISHI MATERIALS HARDMETAL's ROCK TOOLS (Manufacturing company of MITSUBISHI MATERIALS HARDMETAL's ROCK TOOLS), we offer optimum design of button bit by considering the customer’s drilling environment.

Suggest proper way of using rock tools

We suggest how to properly use rock tools, to prevent from early breakage.

We would like to introduce the selection guide of button bit, as it is the initial step to achieving better drilling performance.

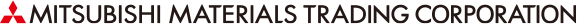

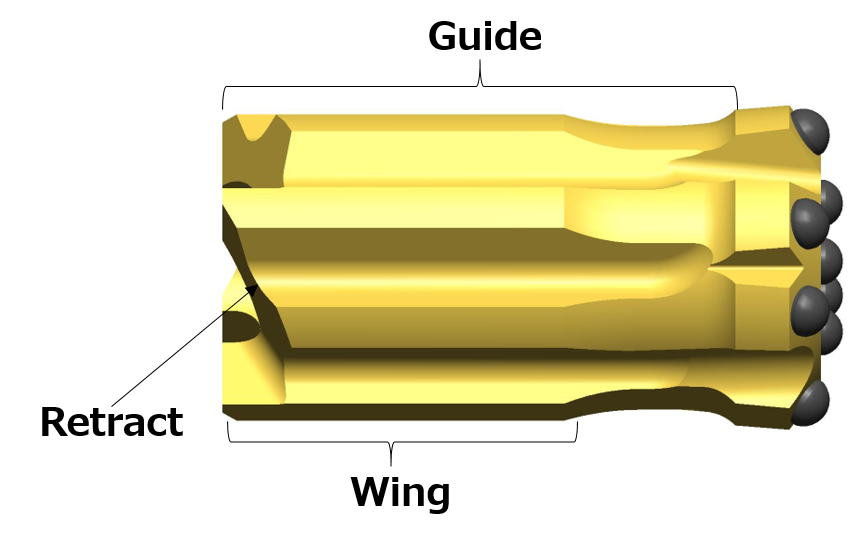

- Terminology of Button Bit

- Bit Selection Criteria

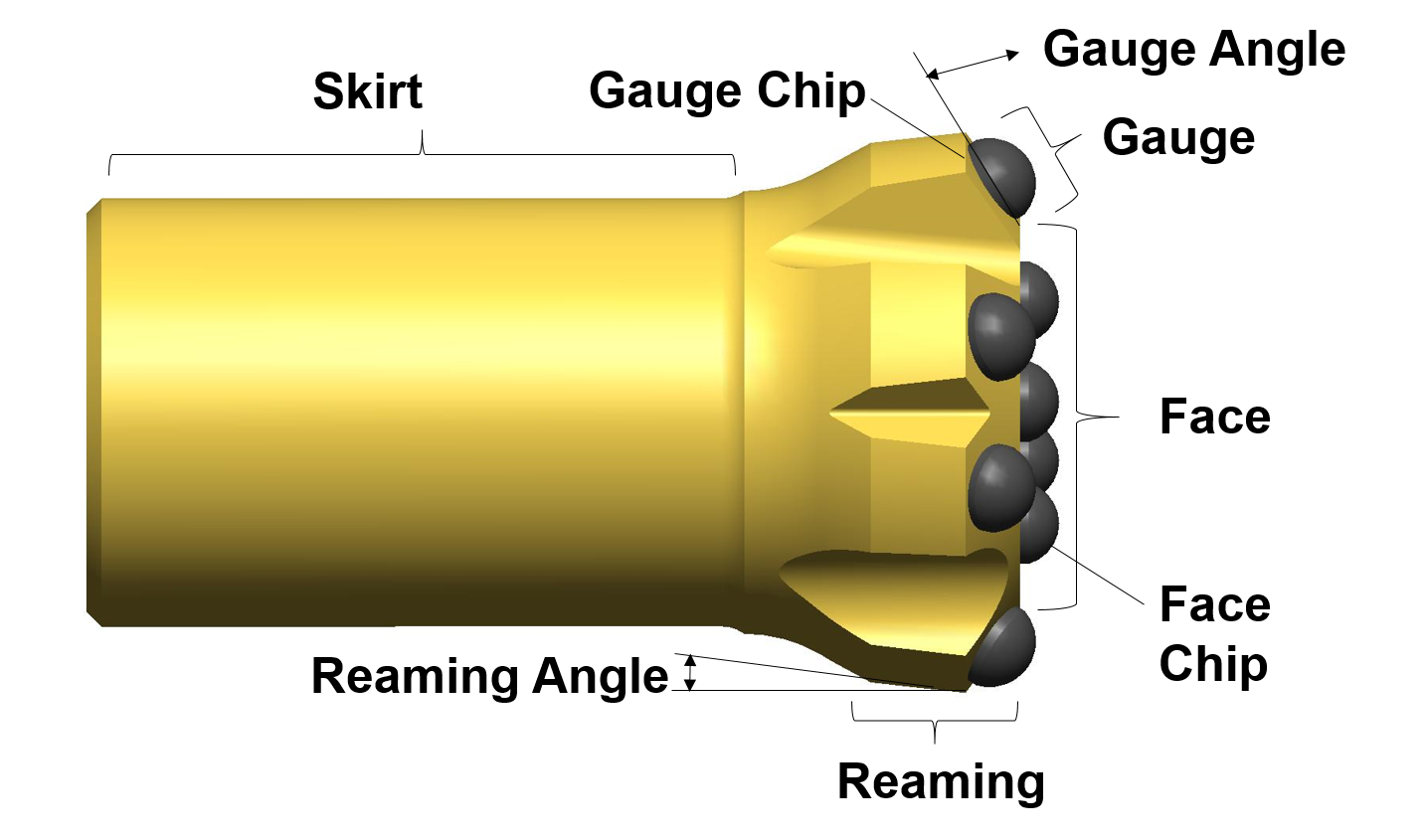

① Thread Type

② Face Design

③ Chip Shape and Grade

④ Skirt Type

①Thread Type

|

DIAEDGE |

R25, R28, R32, R35, R38 |

| Feature |

Good wear resistance |

| Usage |

Tunneling |

T(Trapezodial)Thread

|

DIAEDGE |

M35, M38, M45, M51 |

| Feature |

Excellent wear properties |

| Usage |

For hydraulic drifter |

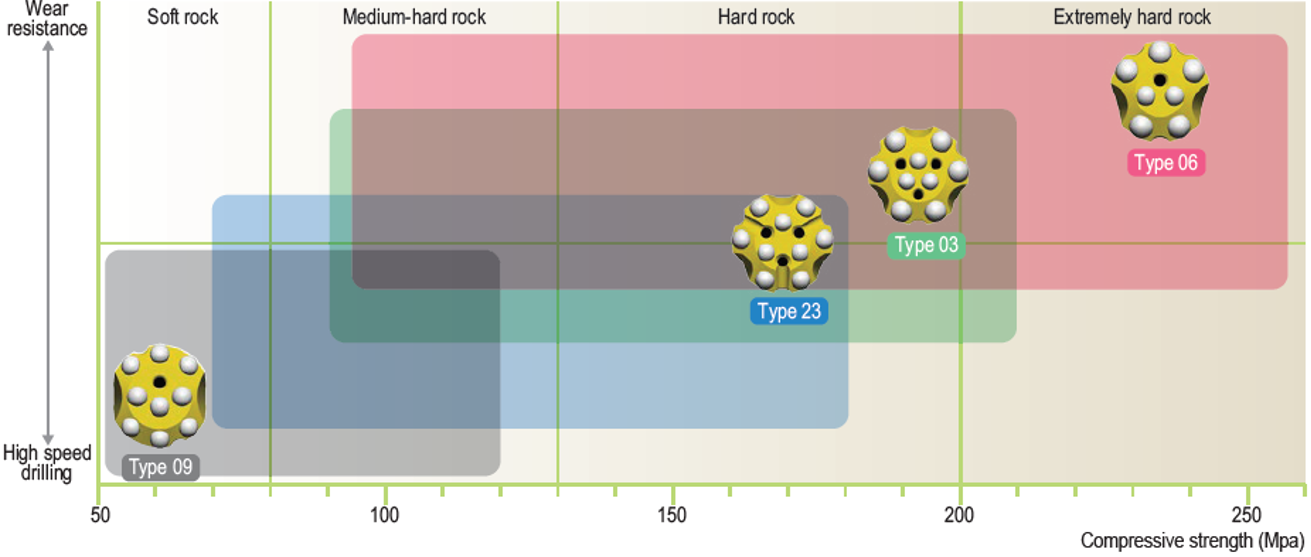

②Face Design

Drifting / Tunneling

|

Speed(Soft Rock) |

Type 09 |

|

Speed |

Type 23 |

|

Wear |

Type 03 |

|

Wear Resistance |

Type 06 |

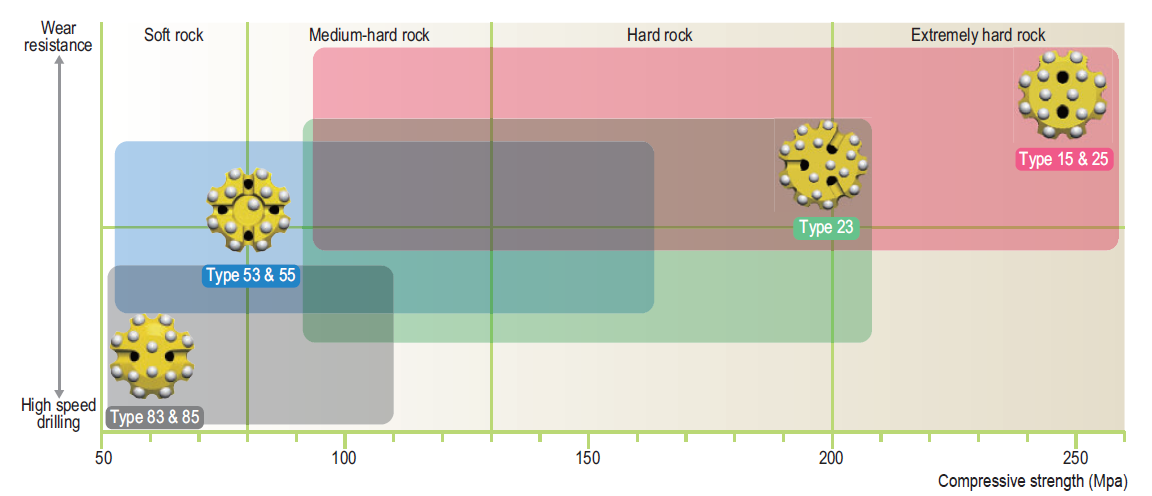

Bench Drilling

| Speed |  Type 83 & 85 |

| Stralghtness |  Type 53 & 55 |

| Wear Resistance/Speed |

Type 23 |

| Wear Resistance |   Type 15 & 25 |

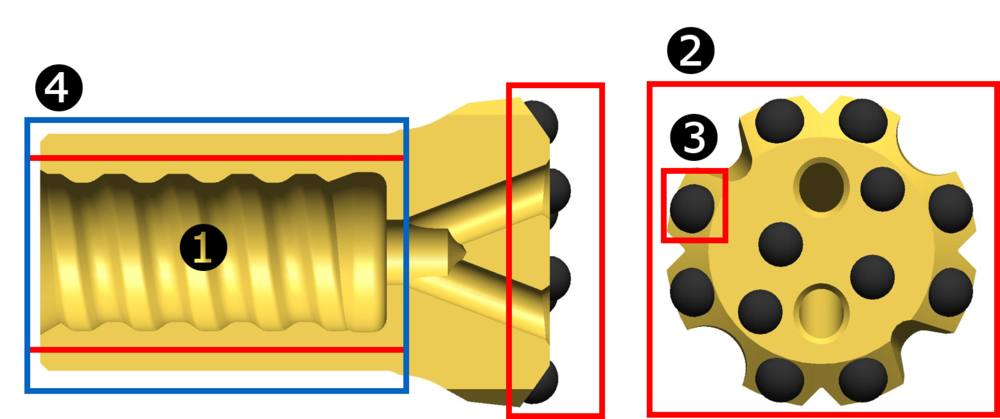

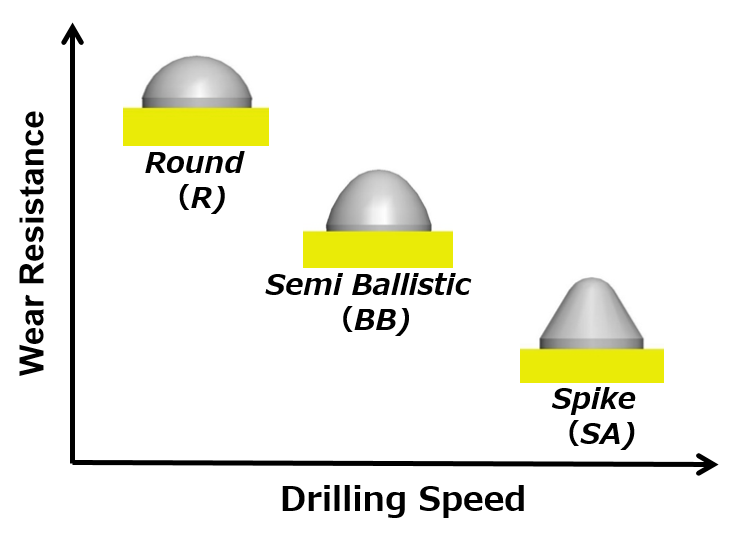

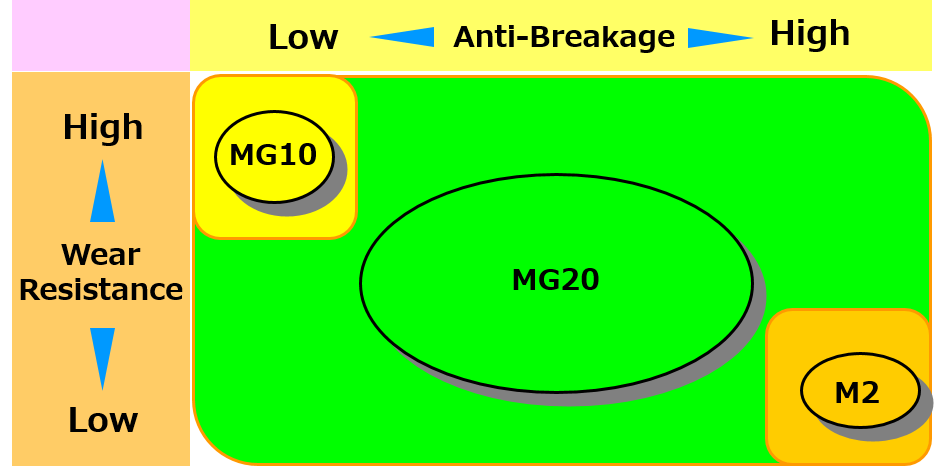

③Chip Shape and Grade

|

Chip Grade |

Feature |

|

Round (R) |

All Round, Hard Rock |

|

Semi Ballistic (BB) |

Balanced in speed and wear resistance |

|

Spike (SA) |

Soft Rock |

|

Chip Grade |

Feature |

| MG10 |

Wear Resistance(High), Hard Rock |

| MG20 |

Standard Grade |

| M2 |

Anti Breakage(High), Soft Rock |

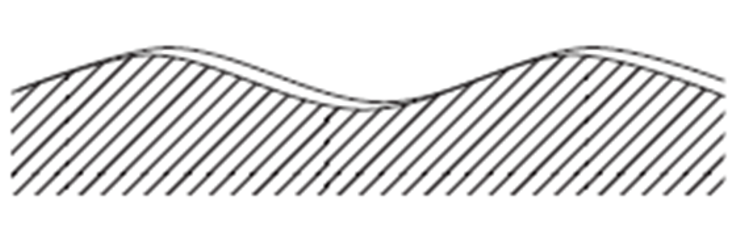

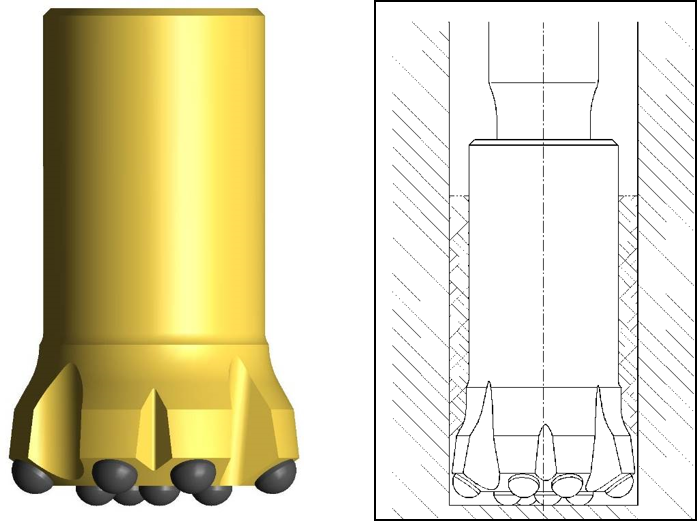

④Skirt Type

Retract Skirt

| Advantage | ・Retract wings help to guide the bit in and out of the hole →For drilling in broken or fissured rock where it is difficult to retract the drill string due to the hole collapse ・Less hole deviation |

|---|---|

| Disadvantage | ・Higher cost(vs Standard Skirt Bit) ・Decrease of flushing efficiency |

About products and services

MITSUBISHI MATERIALS HARDMETAL's ROCK TOOLS(Mining, Quarrying, Tunnel Excavation, Urban Development)

Top Hammer Drilling Tools

Down The Hole Hammer Bit

AGF Tools (Casing advancement system for ground support)

Ultra MaxBit / Super MaxBit (Multifunctional systems for simultaneous drilling and casing)