FSW (Friction Stir Welding)

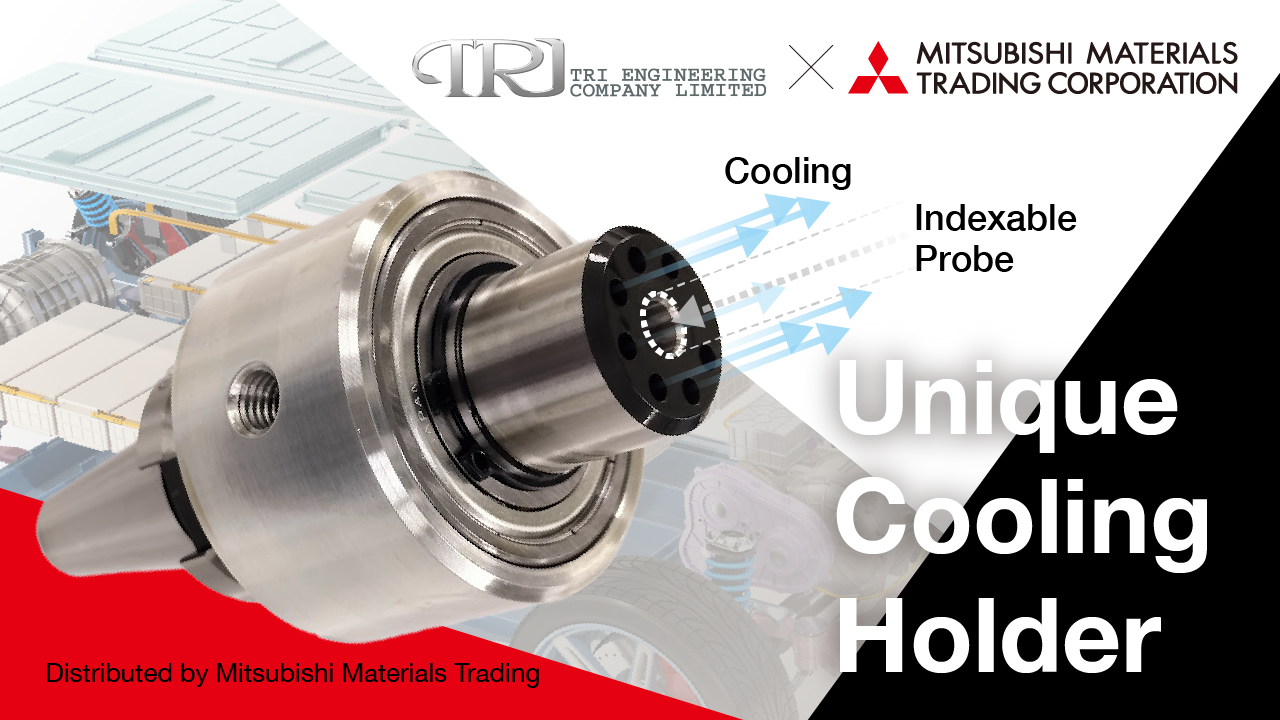

Friction Stir Welding (FSW), known as FSW, was developed as an alternative joining method to fusion welding.

FSW offers various advantages, such as reducing the correction work for joints, minimizing deformation at the joint, and enabling the joining of different materials. Due to these features, it has gained attention in recent years in industries such as automotive and aerospace.

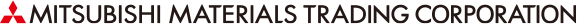

We provide air-through holders which were co-developed with Tri Engineering Co., Ltd. and indexble probes,

For more details, please refer to the video provided.

Hardmetal Products

Product Specifications/Summary

Air-through holder

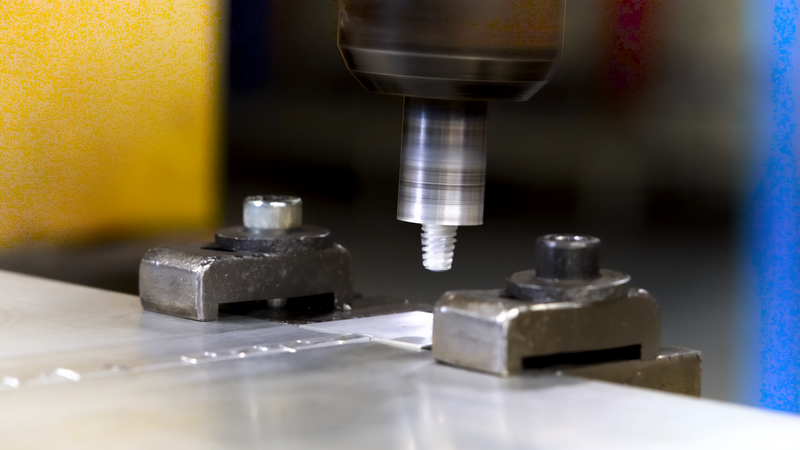

The tool holder for Friction Stir Welding, co-developed with Tri Engineering Co., Ltd., is equipped with a mechanism that efficiently cools the heat generated during the joining process from the inside. This significantly reduces the thermal impact on the robot spindle and the main equipment compared to external cooling. For more details, please refer to the video in the document lineup.

Tri Engineering Co., Ltd. website:https://trieg.co.jp/english/

Indexable probes

The indexable probes, by adopting a indexable type design similar to cutting tools for machining, can significantly reduce running costs. The indexable probe can be used in combination with the tool holder co-developed with Tri Engineering Co., Ltd.

Solid Phase Inc. website: http://solidphase.co.jp/

Terminology

- FSW

- The abbreviation for Friction Stir Welding (FSW). A joining method developed as an alternative to fusion welding.

- Probes

- The tool tip used during FSW (Friction Stir Welding) joining. The part of the tool that comes into contact with the workpiece surface.

- Indexable

- The tip is designed to be indexable. By making the tip detachable, it is expected to reduce running costs.

Line up

Air-through holder