Slot dies

MITSUBISHI MATERIALS HARDMETAL CORPORATION has produced high-precision slot dies using our superior processing technology and under strictly controlled temperatures.

Our slot die coating tools are used for the precision coating of liquid crystal panels, lithium-ion secondary batteries, highly functional films, and other products.

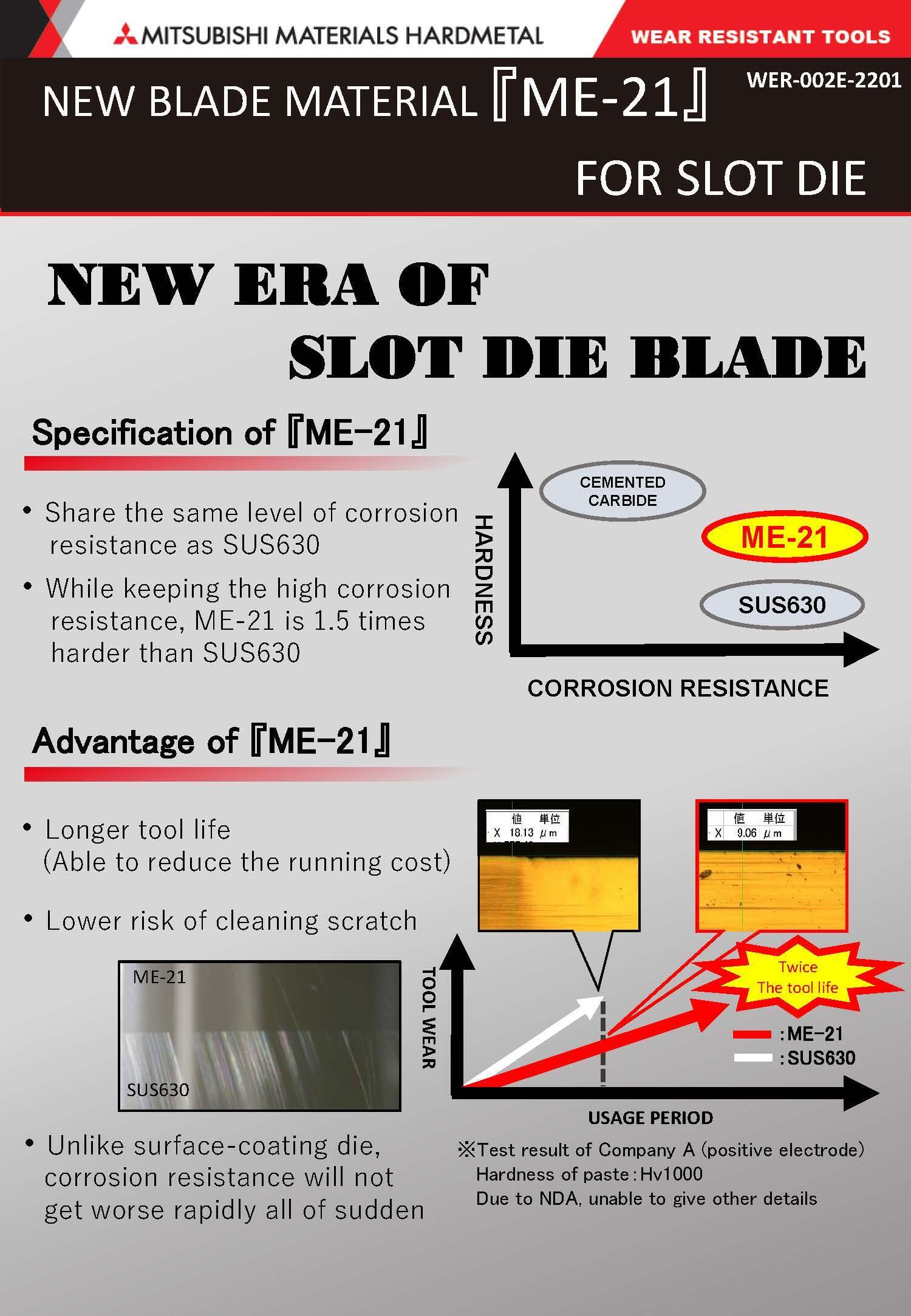

The tips support a wide range of applications, meeting needs such as wear resistance and corrosion resistance. (Customization is possible.)

ElectronicsHardmetal ProductsHardmetal ProductsIndustrial Equipment, Smelting Technology Products, and Auxiliary MaterialsOur Focus Products

Features

Features of MITSUBISHI MATERIALS HARDMETAL slot dies

Meeting the next-generation needs of ultra-precise coating technologies, our slot dies support all kinds of film thickness coatings, from LCDs to lithium-ion batteries.

The features include our original adjustment mechanisms, support for a wide range of applications and fluids, choice of tips (stainless steel/carbide), and long tool life.

With our extensive expertise in fluid and structural analysis, MITSUBISHI MATERIALS HARDMETAL CORPORATION meets customers’ needs and increases coating precision.

Applications

Slot dies are used in a wide range of applications

- Optical films

- Highly functional films

- Lithium ion batteries

- Solar cells

- Fuel cells

- LCDs

- OLEDs

- Smartphones

- Touch panels

- Capacitors

- MLCCs

Product Specifications/Summary

Choice of tip materials and slit width adjustment mechanisms

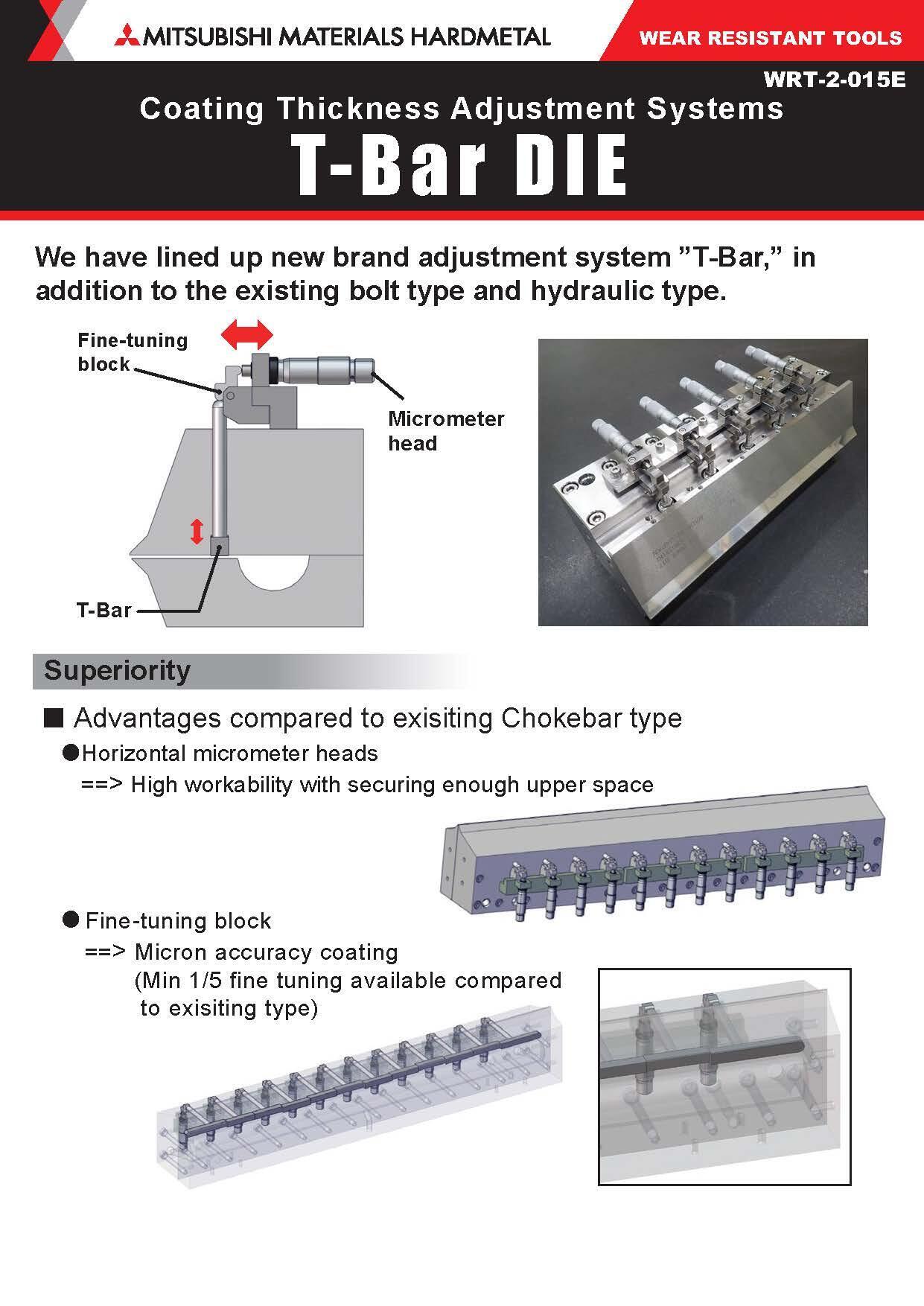

Carbide tip slot die Special corrosion-resistant alloy slot die

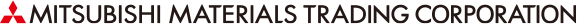

Slot die (tips: stainless steel) Slot dies with a slit adjustment mechanisms (bolt, hydraulic, libero, or T-bar adjustment)

Custom sizing (example)

- Slot die length : 3800 mm max. ・Dry film thickness: 10 nm to 0.7 mm

- Wet film thickness: 3 μm to 1 mm ・Coating liquid viscosity: approx. 1 cps to 50,000 cps

Terminology

- TF15

- Micro-fine cemented carbide with the exceptional advantages of high strength and toughness. TF15 grade cemented carbide optimizes strong edge sharpness and high breakage resistance.

Line up

Slot die