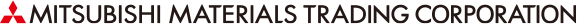

Mitsubishi Materials Trading Corporation — active in the automotive industry

Click the icon for detailed information about the products.

Engines and Powertrains

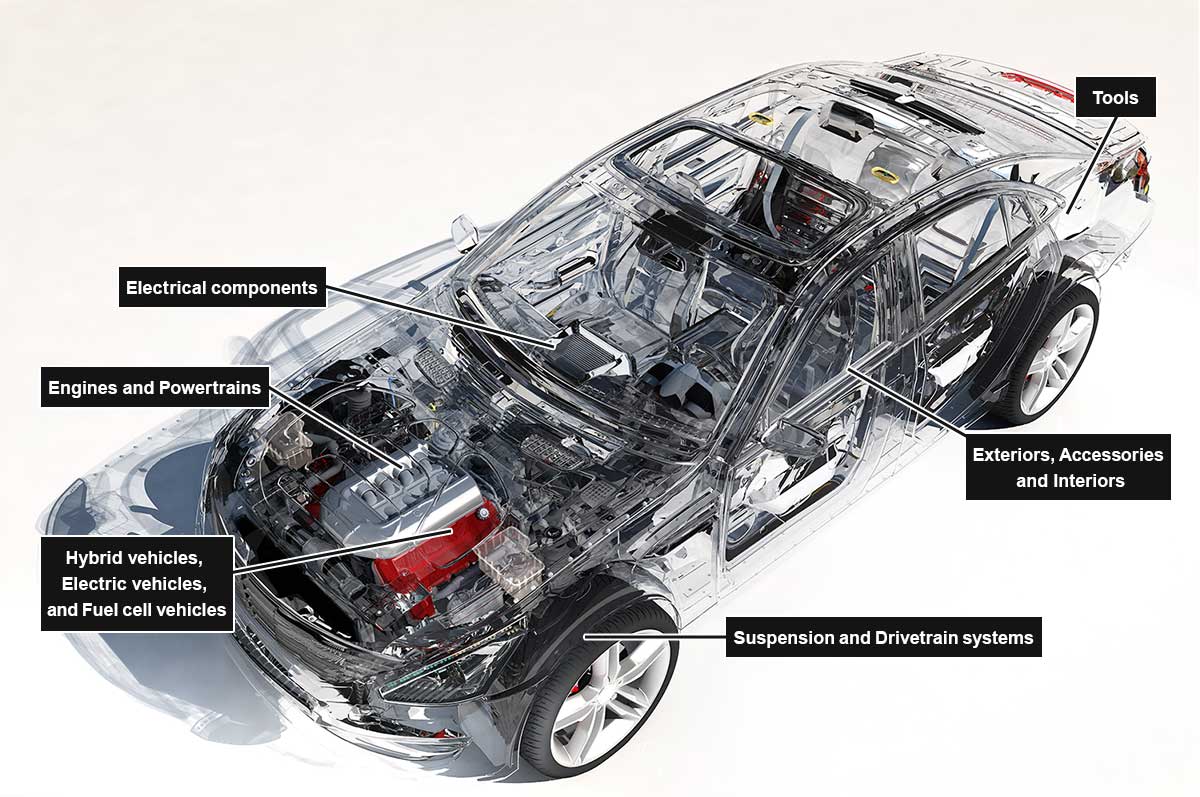

Lighter than iron and nickel and having fairly good corrosion resistance and workability, aluminum is widely used in many industries.

In addition to aluminum materials, we also provide products according to your requests, including processed ones.

We prototype and/or mass-produce automotive parts with very complicated shapes that can be made with press or mechanical processing.

We are able procure various materials including stainless steel, high nickel materials, and aluminum, leveraging a variety of sources inside and outside Japan.

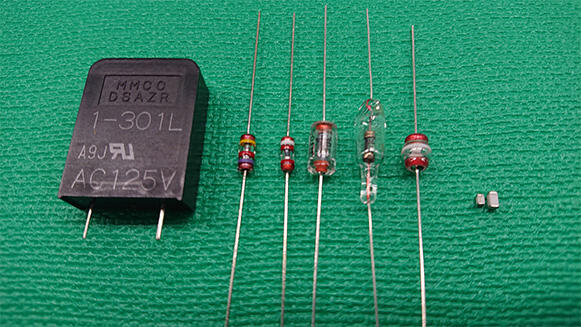

We provide electric contacts based on the appropriate methods, utilizing powder metallurgy process equipment and melt-cast contact manufacturing equipment.

Our melt-cast contacts are made mainly from silver-based materials for automotive and household appliance applications.

Today, electromagnetic relays are widely used due to the electrification of cars.

Our product line consists of dependable cadmium-free contacts featuring excellent welding resistance and wear resistance for smaller, higher capacity relays and switches with longer service lives.

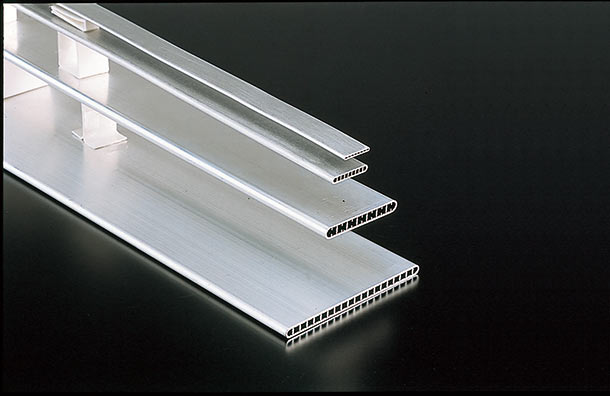

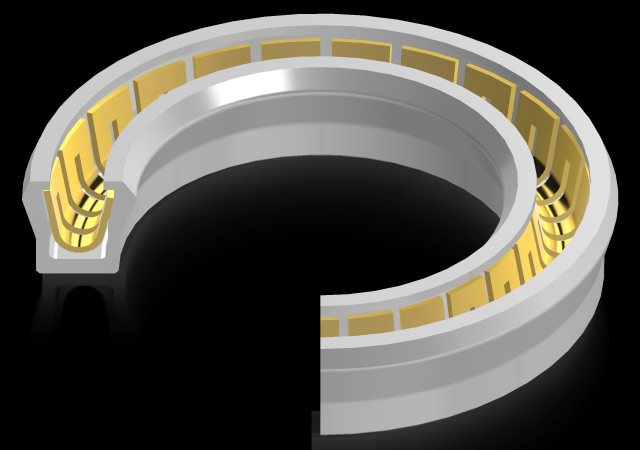

They prolong the service life through improved heat resistance and low friction. We meet your diverse needs by combining various materials (rubbers, resins, and metals) with original shapes designed optimally for your specific use.

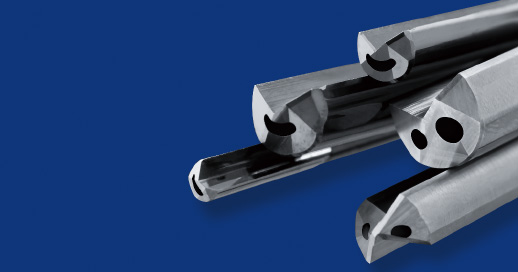

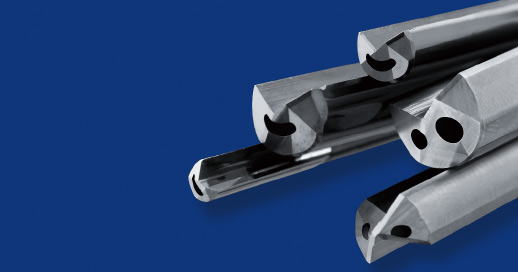

and foreign-made cutting tools

Cutting tools are used for cutting metal into the intended shape.

Cutting tools are manufactured from materials that are harder than work metal.

The metalwowking with this cuttting tools makes large impacts and high heat,

the processing is supported by various shape and methods.

This drill is used for deep hole driling processing. This tool is mainly used for special machines which called gun drill machine.

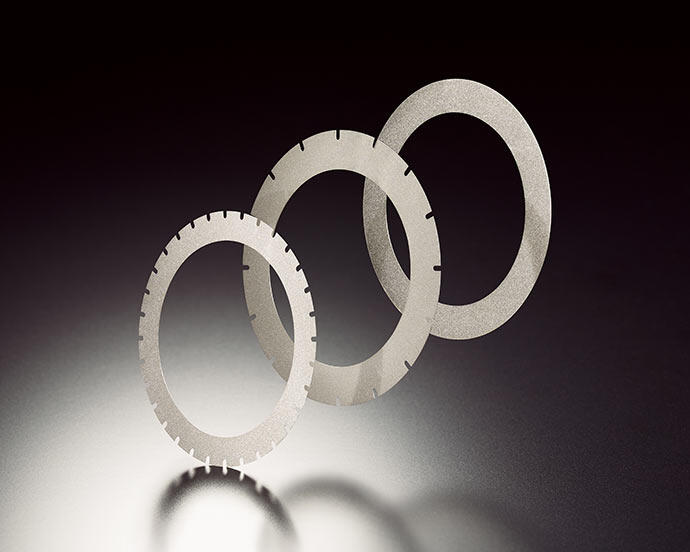

This tool is used for metal final polishing processing.

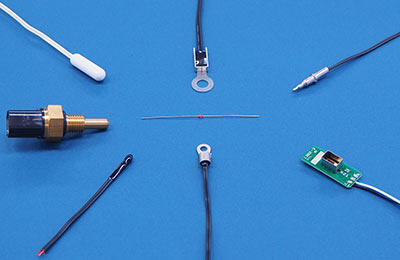

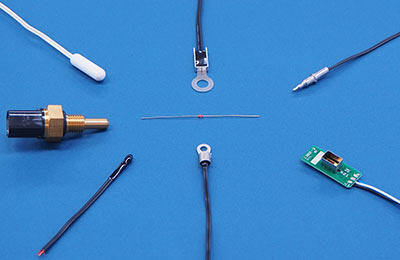

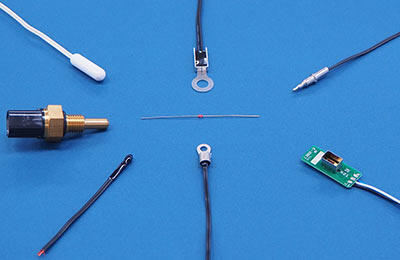

The NTC thermistor uses unique raw materials to achieve high-accuracy temperature measurements.

It includes SMD, lead wire types, and customized types supporting various packaging forms.

The plant-based active enzymes absorb a large amount of oxygen and improve the combustibility of fuel.

The products allow us to propose optimal solutions based on our ability to stably procure materials and high-precision analysis technologies.

Hybrid vehicles, Electric vehicles, and Fuel cell vehicles

The products allow us to meet all needs, starting from the development, design and small-lot prototyping stages.

We provide electric contacts based on the appropriate methods, utilizing powder metallurgy process equipment and melt-cast contact manufacturing equipment.

Our melt-cast contacts are made mainly from silver-based materials for automotive and household appliance applications.

Today, electromagnetic relays are widely used due to the electrification of cars.

Our product line consists of dependable cadmium-free contacts featuring excellent welding resistance and wear resistance for smaller, higher capacity relays and switches with longer service lives.

By combining various materials (rubbers, resins, metals) with a unique optimal shape design, it meets the needs of high-pressure and low-temperature applications related to hydrogen tanks.

and foreign-made cutting tools

Cutting tools are used for cutting metal into the intended shape.

Cutting tools are manufactured from materials that are harder than work metal.

The metalwowking with this cuttting tools makes large impacts and high heat,

the processing is supported by various shape and methods.

This tool is used for metal final polishing processing.

Our wirerod features high purity and almost flawless surfaces, making it suitable for electric wire, windings, trolley wires, and other purposes.

Our wirerod is available in many kinds of materials, including tough pitch copper, oxygen-free copper, silver-bearing copper, and tin-bearing copper.

The NTC thermistor uses unique raw materials to achieve high-accuracy temperature measurements.

It includes SMD, lead wire types, and customized types supporting various packaging forms.

Mitsubishi Materials' microgap surge absorber is a surge protection element for a discharge tube with excellent surge response. It supports various surge protection technologies for power supply lines, communication lines, and static electricity.

Exteriors, Accessories and Interiors

Eliminate cutting work by introducing forging technology and cover printing technology into the pressing process to increase precision.

We guarantee our products, and use equipment to check for any flaws, dents, or scratches stemming from defective materials.

With mold design technology that enables the making of complicated shapes using a single press, we are able to facilitate a number of process by connecting several presses to integrate multiple parts.

Suspension and Drivetrain systems

The products allow us to propose optimal solutions based on our ability to stably procure materials and high-precision analysis technologies.

and foreign-made cutting tools

Cutting tools are used for cutting metal into the intended shape.

Cutting tools are manufactured from materials that are harder than work metal.

The metalwowking with this cuttting tools makes large impacts and high heat,

the processing is supported by various shape and methods.

This drill is used for deep hole driling processing. This tool is mainly used for special machines which called gun drill machine.

This tool is used for metal final polishing processing.

Tools

and foreign-made cutting tools

Cutting tools are used for cutting metal into the intended shape.

Cutting tools are manufactured from materials that are harder than work metal.

The metalwowking with this cuttting tools makes large impacts and high heat,

the processing is supported by various shape and methods.

Electrical components

Mitsubishi Materials supplies AuSn paste, a precision processing material for assembly, which features high accuracy and a high melting point. It can be used for the die bonding of high brightness LEDs, Peltier elements and power semiconductors, etc.

The NTC thermistor uses unique raw materials to achieve high-accuracy temperature measurements.

It includes SMD, lead wire types, and customized types supporting various packaging forms.