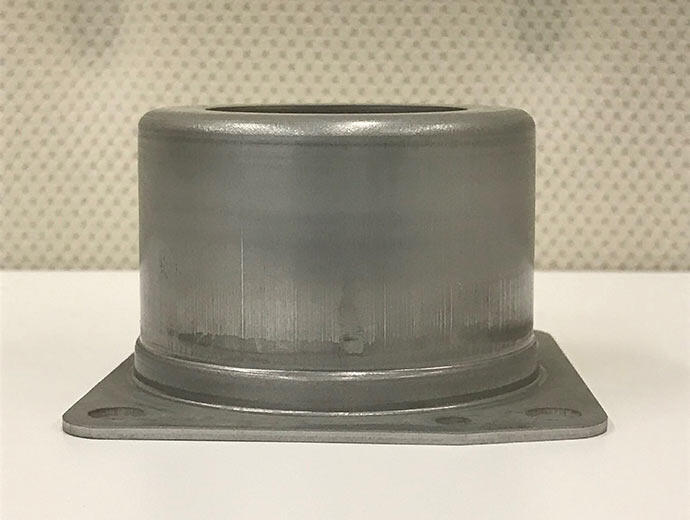

Deep-drawn and Pressed Components

Reducing cost by leveraging the ability to propose optimal shapes and production methods backed by solid technologies

- Challenges faced by customers

- The primary thing that customers want from deep-drawn and pressed components is cost reduction. In addition, there is a lot of demand for optimized production methods that achieve the required costs without lowering quality. The proposal of effective solutions is our mission.

Mitsubishi Materials Trading works continuously with customers to solve the challenge of cost reduction from a long-term perspective.

Solutions

Mitsubishi Materials Trading proposes the change of processes, production methods, and shapes, leading to cost reductions, and also supports customers in other ways from the perspectives of delivery and services.

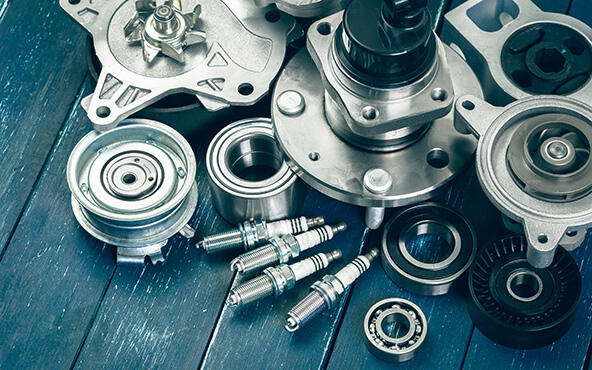

Proposals for the Change of Processes, Production Methods, and Shapes

By introducing forging technology and shaving technology to improve the precision of press working, we will realize no machining.

In addition, by designing molds able to form complicated shapes in a single press process, we also propose solutions for decreasing the number of press operations that must be performed. For example, we decrease the number of processes by coupling multiple press machines together to produce an integrated product (component) that had previously been produced by welding two components together.

When we propose changes to processes, production methods, or shapes, many customers say that it was something they have wanted to achieve. We realize our customers' wishes using solid technologies and enabling costs to be reduced.

Delivery & Service Proposals

We leverage our rich experience and expertise to propose logistics solutions, from packing to transportation methods, that contribute to cost reduction. Our plants, including plants in China and Southeast Asia, enable us to support customers in foreign countries. Reducing the number of customs clearances can contribute to cost reduction. We manage inventories and deliver products for our customers in Japan, to achieve stable delivery.

The Advantages of Mitsubishi Materials Trading Corporation

Since its foundation, Mitsubishi Materials Trading has been involved in automobile parts. All our employees have a passion for manufacturing and wide knowledge of it. This is why we are able to confidently propose the change of processes, production methods, or shapes to customers.

Furthermore, we utilize our expertise and advanced technologies to propose solutions that have broad utility and many applications, beyond solutions for the cost reduction of one specific product.

Proposals That Open Up Options for Customers

In addition to press methods, we can propose an array of production methods to achieve the shape demanded by the customer, for example, sintering, casting, lost-wax and die-casting. We also propose alternative solutions for materials suited to the application.

When a prototype is requested, we strive to maximize our understanding of the goals of prototyping to achieve meaningful prototyping that will contribute to the improvement of customers' technological capabilities in addition to cost reduction. One of our strengths is the ability to open up options for customers and give them the opportunity to select the optimal solution that meets their needs.

Advantages and Benefits for Customers

While cost is the top priority, we review and propose solutions from various perspectives, including proposals for materials, designs, production methods, production processes, and logistics.

Reviewing the existing method from every perspective may lead to the identification of issues and improvements that customers are not yet aware of. Through these proposals, we contribute to customers' accumulation of technology and expertise and their future business outlook.

A message from our representative

"Even when customers request that we handle a single product at first, there are many times where we eventually receive inquiries about building prototypes and working on subsequent phases as they recognize that we are able to provide services in a broad range of areas.

We believe that requests for cost reduction will increase as the number of sensors and electronic devices in automobiles increases. Our mission is to leverage our technologies to produce results that achieve these requests. We strive to be prepared for this. The most important thing is to provide customers with the technologies and components that they need, even in the era of the xEV. We will work to ensure that we achieve a future for automobiles together with our customers."

About products and services

Deep drawing, press components (component combination, machineless forging)

The products are used for automotive parts.