Castings (precision casting, die casting, gravity casting)

Leveraging the most advanced technologies and the latest information to ensure that our automotive casting components are more cost competitive

- Challenges faced by customers

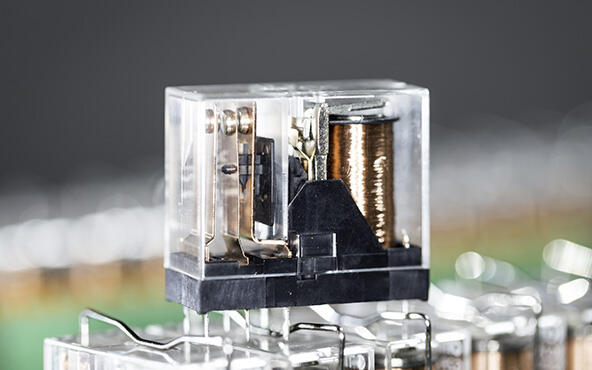

- Today, competition in the global automobile industry is severe, as is price competition in the industry. The biggest challenge that customers must achieve to survive amid this global competition is ensuring their cost reductions are compatible with consistent quality. As price competition has increased globally, the cost performance of casting has reached its limits. This is not a simple question of reducing costs by switching procurement to foreign countries with lower personnel expenses. Even in this severe market environment, Mitsubishi Materials Trading provides the things its customers desire, cost reductions and consistent quality.

Solutions

We consider and discuss all parts of a process involved in the product our customer desires, from manufacturing to delivery. In this way, we are able to propose solutions that reduce costs while ensuring quality consistency and improving it from many different perspectives.

Discussion on manufacturing methods

We will discuss optimal manufacturing methods (casting, forging, press, sintering, cutting and sheet metal) in terms of cost and quality, and encompassing a review of engineering methods, including a discussion of materials.

Selecting optimal manufacturers to send orders to

We create a list of overseas manufacturers specialized in specific manufacturing methods and survey their history of making products that are similar in terms of shape, to the product the customer desires. This enables us to select the optimal manufacturer to send an order to.

(We may select from domestic manufacturers where appropriate.)

Our promise of quality

We repeatedly meet closely with the customer about the shape and specifications of their product. When proposing solutions that may involve a change in the manufacturing process, we provide a more in-depth explanation to enable the customer to understand that there are no problems in the product's quality. After that, a product sample is submitted and is evaluated before a contract is signed.

Proposals for reduction of indirect costs

We review our customers' cost structures and propose measures to compress them. This applies to direct costs relating to manufacturing, as well as indirect costs including transportation costs incurred up to product delivery and, where inventory control is necessary, warehouse costs.

The Advantages of Mitsubishi Materials Trading Corporation

We leverage our strengths in technologies, networks, experience and other areas to support the delivery of the products our customers need.

Accumulation of experience in automotive manufacturing and components

We have dealt in automotive components for more than 70 years, and are familiar with a process of automotive manufacturing and the level of quality that an automotive component is required to meet. We work to understand the customer's expectations regarding the shape and specifications of a product one by one, to confidently propose solutions for issues such as a change of a manufacturing method.

Extensive international network and information gathering capabilities

Utilizing our overseas locations in eight different countries and regions, we gather industry information and work to discover good manufacturers. To date, we have partnered with manufacturers from China, Taiwan, Thailand, Vietnam and Indonesia, in an effort to strengthen our readiness to meet the diversifying needs of customers.

Ability to flexibly react to the customer's situation

We are able to also provide support for activities other than direct product supplies. Our flexible services are adaptable to the way that the customer wants its orders to be handled, such as systems including orders by lots, inventory control and delivery using the kanban method.

Benefit for customers

Customers want to reduce costs by all means. However, independently pursuing cost reduction entails a heavy burden. We step in for our customers to take on the challenge of cost reduction, providing diverse value in terms of:

- Selection of reliable manufacturers to send orders to;

- Technical guidance for the manufacturers and quality control;

- Consistent procurement of cost-efficient, high-quality products;

- Proposing many different solutions to reduce costs leveraging our advanced specialization;

- Consistent supply of products through support for deliveries and other activities; and

- Provision of information, proposals and technical advice while keeping on top of the most advanced technologies, and many other benefits.

In this way, we contribute to the enhancement of customers' productivity and competitiveness.

In fact, many of our customers who have achieved the compatibility of cost reduction and quality consistency seek advice from us about how to introduce the same approach for other products to reduce costs.

A message from our representative

"Our missions are to continue meeting all of the needs of customers and become more cost competitive. The growing popularization of EVs and HVs should bring a surge of changes to the automotive components industry. Our role of supporting customers will take on greater importance. To be constantly ready to meet expectations in any situation, we will go beyond customers' expectations to gather information and research the industries involved and combine this knowledge with our accumulated technical strengths and abundant knowledge and wisdom about the industry. In doing so, we will join customers to create new value."

About products and services

Castings (precision casting, die casting, gravity casting)

We are capable of working with a variety of techniques beyond casting iron, stainless steel, high-nickel alloys, aluminum, etc. and have a lot of suppliers in Japan and other countries.