Electric contacts for automobiles, electric contacts for home appliances, power contacts

Advanced specifications and cost competitiveness achieved through our unique material structure control technology

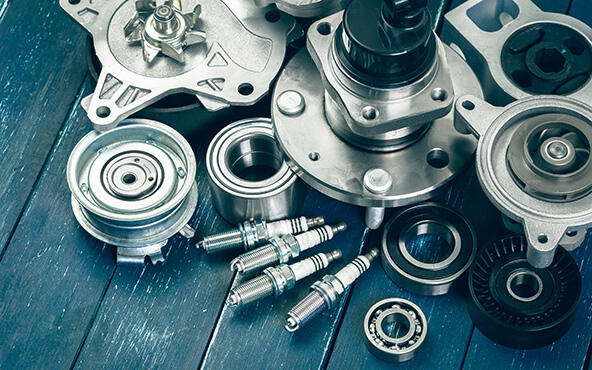

Mitsubishi Materials Trading supplies a variety of electrical contacts, many of which are made from silver-based materials. Our main products are automotive relays that operate power windows and wipers delivered to Tier 1 suppliers. Based on the technologies we have cultivated in the highly competitive automotive components industry, we also provide a range of consumer relays operating home appliances.

- Challenges faced by customers

- Customers demand that our electrical contacts achieve advanced specifications that are up to the needs created by the evolution of the products in which the electrical contacts will be installed. In particular, automotive electrical contacts demand high performance, following the evolution of the automobile itself, including developments such as the emergence of hybrid and electric vehicles.

Moreover, amid today's intensifying competition in the automotive components industry, the reduction of cost while improving performance is an ongoing challenge.

Solutions

With our customers' needs as a starting point, Mitsubishi Materials Trading always considers challenges from every perspective to provide solutions to our customers.

New Materials Proposals

Leveraging our unique processing technology to control material structures, we propose the development of materials and material properties that are best suited to our customers' needs. By customizing materials and their properties, we can improve their specifications, such as the improvement of welding and wear resistance, and the achievement of low contact resistance. Excellent welding and wear resistance lengthen the service lives of contacts, while low contact resistance reduces the amount of heat generated.

New Manufacturing Methods Proposals

We review our existing products, including their manufacturing methods, to propose products in shapes that are optimized for our customers' needs. Shape customization enables smaller, more compact designs to achieve space saving and cost reduction at the same time. In particular, our technique for producing smaller-sized and reduce-silver contacts can reduce the use of silver. This is key in cost reduction, and has been praised by our customers.

The Advantages of Mitsubishi Materials Trading Corporation

Ability to detect and precisely understand challenges

Our specialists are well versed in materials' electrical properties, ensuring that a high level of expertise is always a part of our operations. Our experts will thoroughly identify the needs of our customers and the challenges they face, and precisely understand the elements necessary to identify a solution.

Ability to deliver ideal solutions

Our business record of handling a wide range of automotive components stretches back to our founding. Our experience and expertise working with automotive electrical contacts was accumulated over this long period. This experience that is our competitive advantage enables us to match our customers' needs to the employment of our manufacturing contractors' technologies to deliver ideal solutions.

Offering delivery and service support to our customers

We have manufacturing and sales locations in China, and an established global supply system to meet our customers' needs. In addition, we are also capable of managing and delivering inventory, and responding flexibly to requests for our customers in Japan.

Advantages and Benefits for Customers

Contributing to the advancement of the customer's technologies

The production of automotive electrical contacts with advanced specifications starts with the development of new materials that meet the needs of the customers. This task involves the incorporation of an array of original, innovative efforts focused on multiple points in the process, including design and manufacturing methods. These tasks require continuing experimentation, often evaluating choices between two or more conflicting factors, as enhancing one particular performance field may sacrifice another.

Throughout the entire process, which may take several years, we value communication with our customers, and seek out and propose optimal solutions in close cooperation with our manufacturing contractors. We believe that our proposals for materials, shapes, and manufacturing methods will contribute to the development of electrical contacts, and also to the advancement of our customers' technologies.

Our environmental friendliness adds value

We deliver a wide range of products with advanced specifications, while extending the technologies and expertise cultivated through the intensifying quality and cost competition surrounding electrical contacts for automotive components and household appliances.

We also have a lineup of cadmium-free contacts for applications in automobiles and household appliances. As sustainability has become a global issue, we believe the value we add through our environmental friendliness will become even more important in the future.

A message from our representative

"Developing electrical contacts is a long-term project that requires persistent effort. Therefore, building trust with customers is vital, and we dedicate ourselves to these projects, keeping our ability to respond to customers in good faith our top priority.

Into the era of IoT, too, we expect the role of contact products to expand drastically. As this happens, contacts will relay data, not electricity. Although this will be technically more difficult, we will happily fulfill the roles that the times demand, while making our strengths in the bridging needs and technology available to our customers."

About products and services

Electric contacts for automobiles, electric contacts for home appliances, power contacts

Ag-SnO²-In²o³(silver-tin indium)、Ag-SnO²(silver-tin)、Ag-Ni(silver nickel)

Ag-ZnO(silver-zinc)、Ag-CuO