Tools and accessories related to machine tools

Mitsubishi Materials Trading provides one-stop solutions for your machining process.

We will propose one-stop proposals related to the machining process by focusing on tools, materials, equipment, and metal recycling.

【Machine Tools】 Cutting tools / Grinding tools / Deburring tools / FSW tools / Regrinding + Recoating

【Materials】 Metal materials / Additive manufacturing

【Accessories】 Fixture/ Air Coolant nozzles / Holders / Measuring instruments

【Environmental solutions】 Non-ferrous metal purchasing / Scrap automatic compactor

Hardmetal Products

Features

Introduction video for tools and accessories related to machine tools↑

Product Specifications/Summary

Machine tools

Cutting tools

In addition to Mitsubishi Material's cutting tools, we offer various cutting tools such as brazing tools, HSS tools, PCD tools, gun drills, and exchangeable-head end mills. We propose the optimal tools tailored to customer's needs, and our tools will contribute to solving challenges in the machining process.

detail page:https://www.mmtc.co.jp/en/products/cuttingtools.html

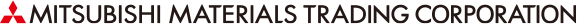

Grinding tools

We offer various diamond wheels such as resin bond wheels, metal bond wheels, vitrified bond wheels, and electroplated wheels. We propose the optimal grinding wheels tailored to our customer's needs and our wheels will contribute to solving challenges in the machining process.

detail page:https://www.mmtc.co.jp/en/products/diamondwheels.html

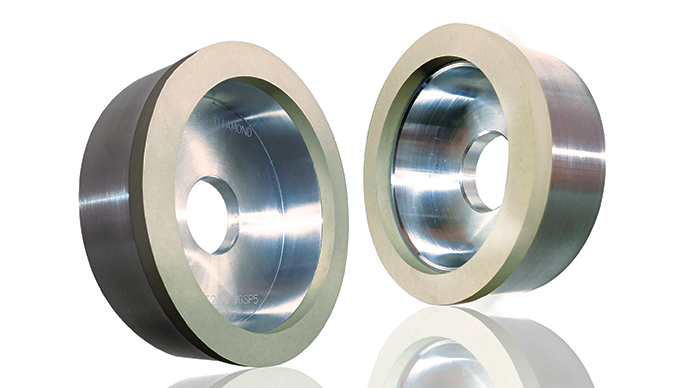

Deburring tools

We offer deburring tools such as carbide tools, HSS tools, and ceramic tools.

FSW tools

We provide air-through holders and indexable probes developed in collaboration with Try Engineering Co., Ltd.

Additionally, we have entered into an advisory contract with Solid Phase Co., Ltd. regarding bonding technology, and we are working on further enhancing the functionality of our products.

detail page:https://www.mmtc.co.jp/en/products/fsw.html

Regrinding + Recoating

We also provide regrinding and recoating services. We recommends the best coating option based on the specific machining conditions, utilizing our range of coatings. We ensure high-precision coating with a short delivery time.

Metal materials

We offer a variety of alloys, including copper alloys, heat-resistant alloys, corrosion-resistant alloys, powder alloys, and carbide alloys, all tailored to meet our customers' needs.

Additive manufacturing

We offer a complete service using metal 3D printers, which includes powder development, prototype production, and mass manufacturing.

Accessories

Fixture

We design and manufacture optimal jigs tailored to our customers' needs.

Air nozzle

We offer air nozzles used for water removal, drying, cuttings removal by blowing compressed air. Based on factors such as blowing force, blow pattern, and nozzle material, we propose the most suitable product for your needs.

Coolant nozzle

We also offer specialized tools for cleaning workpieces and the interior of machine tools using coolant.

Holder

We offer standard tool holders by each manufacturer, and custom tool holders with special shapes are also available. It is possible to manufacture tool holders integrated with various types of interfaces.

Measuring instruments

We offer various equipment, including tool measuring instruments and balancers.

Environmental equipment

Non-ferrous metal recycling

We also purchase used tools such as tungsten-carbide tools, cermet inserts, HSS solid end mills, drills, etc. Mitsubishi Material Group is engaged in recycling activities that involve collecting used tools and regenerating them as materials.

Scrap automatic compactor

We handle equipment that automatically compacts metal cuttings generated during machining processes. By compressing bulky cuttings and turning them into briquettes, they can be processed efficiently. This is ideal for cuttings handling during metal processing.

Terminology

- Regrinding

- It involves regrinding used tools to restore them to the same shape as brand-new tools.

- Recoating

- It involves applying a new coating to regrinded tools.

- FSW tools

- It is an abbreviation for Friction Stir Welding (FSW), a metal joining method that utilizes frictional heat generated by rotation, allowing for high joint strength without the need for melting.